Single shaft Paddle Mixer

The gravity-free mixer is mainly suitable for the mixing of dry and non-viscous powders, and can also be used for the mixing of two or more materials with different densities and particle sizes. Mixing and stirring is an important link in the production process of dry mortar. With the innovation of technology, our company has developed a new single-shaft gravity-free mixer.

- Single shaft or twin shaft

- High speed, 90r/min

- Bomb bay discharge, no residue

- Hydraulic discharge door

- 1.5-20 CBM

Introduction

The gravity-free mixer is mainly suitable for the mixing of dry and non-viscous powders, and can also be used for the mixing of two or more materials with different densities and particle sizes. Mixing and stirring is an important link in the production process of dry mortar. With the innovation of technology, our company has developed a new type of double-shaft and single-shaft paddle weightless mixer.

1. Fast mixing and good uniformity. It can fully turn the material evenly in about 180 seconds.

2. The hydraulic large door has less residue, and the unique door structure can enable the material to be discharged within 10 minutes, and the material will not leak during the mixing process.

3. The adopted industrial gear box replaces the traditional chain drive. Smooth operation, no vibration supply, simple and convenient maintenance.

4. Replaceable wear-resistant paddles and stuffing box wear-resistant sleeves ensure that the production of 300,000 tons of mortar does not require replacement of paddles.

Features

- Fast mixing speed, mixing time per batch: 3-5min, high mixing uniformity;

- Materials with large differences in specific gravity, particle size, shape and other physical properties are not easy to segregate when mixed;

- The mixer is equipped with a high-speed rotating flying knife group, which can quickly and effectively disperse fibrous materials

- Tonnage power consumption is small, 60% lower than ordinary horizontal ribbon mixer;

- Wide range of applications, manganese steel, carbon steel, semi-stainless steel, and all-stainless steel are used according to user needs, especially for mixed production of high-precision materials.

UHPC mixers

1. The planetary mixer is suitable for mixing all high-quality concrete (dry-hard, semi-dry-hard and plastic concrete) and achieve high quality in the shortest time. It can also be used in glass, ceramics, refractory and other industries.

2. The specially developed reduction box can effectively distribute the power balance to each stirring device, and even under harsh production conditions, it can also ensure the low-noise transportation of the stirring university. At the same time, it saves more space. Compared with the traditional gearbox, the maintenance space of the mixer can be increased by 30%.

3. The elastic coupling and hydraulic coupling (optional) can effectively protect the transmission system from the impact of overload.

Mixing diagrams

This diagrams show the perfect mixing action of the planetary mixer from 6 to 60 seconds after the material is added. Note that the floor is completely swept by the action of the mixing stars every 4 revolutions (6 seconds) and that each zone is covered at regular intervals in time.

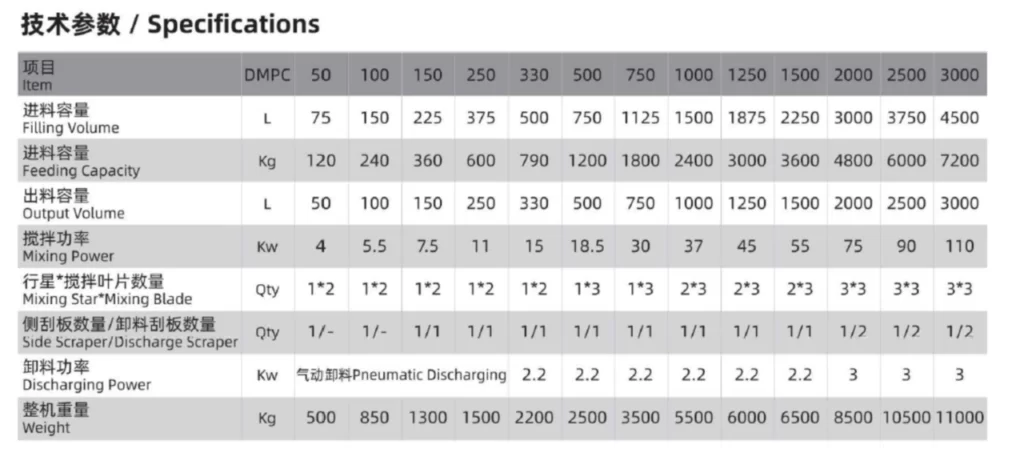

Specificaitons of planetary mixers

Plough mixer

The Plough mixer is composed of four parts: a circular cylinder, a transmission mechanism, a Plough and a flying knife; when working, the Plough moves in a circular motion, and the material is divided into two directions by the Plough blade surface to form a bidirectional material flow, which is different from the two. The materials shunted by the side Plough cross each other to form convection. When the material flows through the high-speed flying knife, it is sheared and thrown by the high-speed flying knife blade, so as to achieve uniform mixing in a short time. The mixing accuracy of this machine is high, and no segregation occurs during mixing, especially for materials that are easy to agglomerate, it can play the role of deagglomeration and dispersion.

In the process of mixing lithium battery materials such as ternary precursors, the plough mixer is a necessary choice; the equipment is composed of a horizontal main shaft, a stirring plowshare or paddles with reasonable distribution of static balance to form a stirring part. The cylindrical barrel contains one or more feeding ports, an exhaust port, a central outlet, etc. The two end faces of the barrel are respectively fixed by the vertical plates on both sides. In the industry, multiple sets of flying knives are often selected together. It is added to the mixing process, and the power drive system and the cylinder are designed separately. This model makes the powder produce a centrifugal throwing convection movement under the combined action of the plowshare and the flying knife blade, which is fully mixed with each other in a short time, and is widely used in the lithium battery industry.

Application range:

It is widely used in construction material, chemicals, medicine, agricultural medicine, food, feed and feed additives,

dyes, paints, plastics and other industries, such as solid – solid (powder and powder), mixed solid-liquid (add a small amount of powder in liquid) and wet granulation, drying and composite technology. It is especially

suitable for the mixture of viscous or rubbery additives.

Character:

- Short mixing time, can mix the materials that are big difference in granularity and density.

- work under sealed condition, run stably, dust concentration is low, no pollution to the environment.

- Can add spraying device, can separate and mix the lump materials.

- It has the best performance of separating the fibers.

Conical mixer

The stirring part of the conical mixer is a long spiral or two asymmetrical spirals; while they rotate (rotate) around their own axis, they also rotate around the central axis of the conical container along the inner wall of the conical container by means of the rotation of the cantilever. Planetary motion (revolution); the equipment repeatedly lifts the material through the public and rotation of the screw, and generates compound motions such as shearing, convection, and diffusion in the cone, so as to achieve the purpose of uniform mixing. The advantages of this machine are that it has a wide range of applications, large volume, no residue in the discharge, and energy saving.

Conical mixer is suitable for mixing powder with powder, granule with powder, powder with a small amount of liquid, and is widely used in chemical industry, dyestuff, pigment, pesticide, veterinary drug, medicine, plastic and auxiliary industries. The machine has wide adaptability to mixtures, does not produce overheating for heat-sensitive materials, can maintain the integrity of particles as much as possible for granular materials, and has good adaptability to the mixing of coarse powder, fine powder, fiber or flake material. The machine can also make various special forms such as heating, cooling, positive pressure, vacuum and so on according to the requirements of users.

Horizontal Ribbon Mixer

The horizontal ribbon mixer is composed of a U-shaped cylinder, a ribbon stirring blade and a transmission part; the ribbon blade is generally made of double layers. When working, the outer ribbon collects the materials from both sides to the center, and the inner ribbon The material is conveyed from the center to both sides to form convection mixing. The stirring part can also be made into a paddle type or add a flying knife to adapt to different materials. The cylinder cover can be made into an arched or fully open type, the arched shape can bear pressure, and the fully open type is convenient for cleaning the inside of the equipment. The advantages of this machine are wide application range, high mixing uniformity, short mixing time and large loading coefficient.

Horizontal ribbon mixer is suitable for mixing powder and powder, granule and powder, powder and a small amount of liquid. It is widely used in chemical, pharmaceutical, food, feed, plastic and building materials industries, and can be produced according to GMP standards. The machine has wide adaptability to mixtures, can mix viscous materials evenly, and can keep particles as complete as possible for granular materials. The machine can also make various special forms such as heating, cooling, positive pressure, vacuum and so on according to the requirements of users.

Dual Motion Mixer

JHX series double-motion mixer, its main function part is composed of lower rotating double-cone container, plus rotating shaft and inner spiral blade parts. Components at different speeds are driven by one powertrain. Special sealing parts are used to seal between the rotating shaft of the helical blade and the container. When unloading, the user can operate the forward or reverse shake button on the panel to shake the container partially, and rotate the blade to speed up the unloading. All contact parts of this machine are made of high quality stainless steel.

1. The two major functions of the container rotating around the inclined axis are to completely eliminate the dead angle at the bottom of the container, so that the left and right and upper and lower convection of the mixture directly participate in the mixing.

2 The relatively fast helical blades play a major role in mixing. Furthermore, the helical blades include inner blades and outer blades. When the inner blade rotates, the mixture can be stirred vertically, while stirring from the middle to the sides. So our machines can mix materials more evenly. In addition, there are functions such as cutting and striking of the spiral blade. After rigorous testing, in the field where the mixing requirements of metal alloy powder are very strict, if customers use traditional V-type mixers, it will take a long time (some customers use V-type mixers for 24 hours) to reach the mixing standard, but customers It only takes half the time to be up to par with our mixers. If the powder is a regular type, a few minutes will do.

3. This series of machines has a good mixing effect on powders with large differences in specific gravity. Due to the downward pressure on the powder by the rotating screw blades inside the machine, the floating light powder can be pressed into the heavy powder and mixed completely.