Other dry mortar mix plant Accessory Parts

Screw conveyor

Tubular screw conveyor and feeder systems are extremely versatile and offer a variety of standard solutions for conveying powder or granular materials. Different models of conveyors or feeders are available for various applications such as concrete production (for powder ash, filler dust, silica fume), pre-mixed building materials (dry gypsum, sand, cement, additives), glass processing ( calcium carbonate, soda, sand, etc.), foundries (sand, bentonite), etc.

Diameter: 114mm,139mm,168mm,193mm,213mm,273mm,325mm.

Silo

The cement silo is a closed tank for storing materials. It is generally suitable for the storage of bulk cement and other bulk materials in construction projects, road and bridge water conservancy or component plant construction. It can also be used for batching equipment for bulk cement storage in mixing plants. The equipment is waterproof, moisture-proof, and cement loss-proof, with small footprint, long service life and low cost. It is an affordable choice.

Storage capacity: 30-800Tons

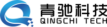

Air compressor

Provide high-pressure air source for all production line, open and close butterfly valve, pulse dust collector, mixer unloading, packaging and filling machine, they all need to use compressed gas.

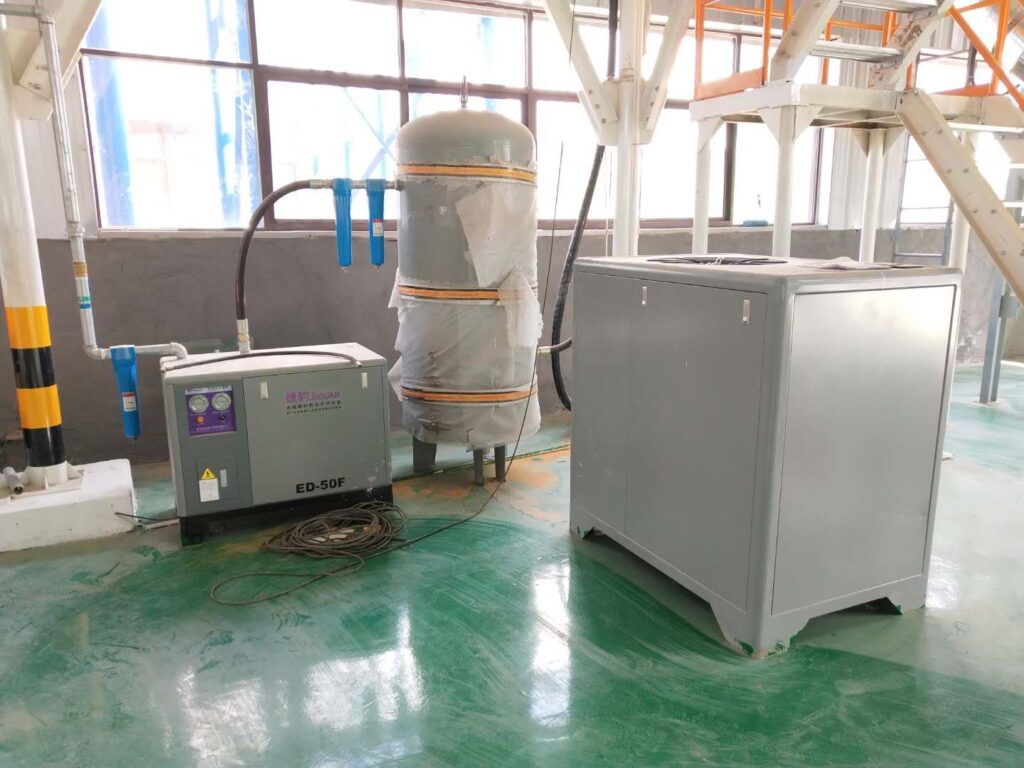

Pulse dust collector

The dust remover takes compressed air as the dust removal medium, releases the compressed air in an instant through the pulse injection mechanism, and the high-pressure air induces the surrounding air to shoot into the filter bag at a high speed to make the filter bag expand rapidly. The dust accumulated on the surface of the filter bag falls off by means of impact vibration and reverse air flow. The cleaned dust falls into the ash collecting hopper and is discharged from the body through the bottom ash discharge valve. The design has the characteristics of compact structure, convenient maintenance, large ash removal kinetic energy and high ash removal efficiency. It is widely used in the purification of dusty gas in building materials, mining, chemical industry, coal, powder processing and other industries. It is an ideal choice for environmental protection and dust removal.

Automated control system

The control system of our company’s mortar production line consists of computer system, electronic batching system, operation console, strong electric cabinet and so on. Hardware and software integration, fully automated. Convenient parameter setting, one-click completion of production parameters. All-round online real-time detection of equipment production status, and safety chain control. If an abnormal working condition occurs, the equipment fault point can be accurately reminded to remind the staff to conduct positioning inspection and maintenance, so as to realize the fault location and elimination, thereby improving the production management level, ensuring equipment safety and improving economic benefits.

Plate chain elevator

NE plate chain bucket elevator is a plate chain type, gravity-induced discharge lifting equipment. It is suitable for vertical conveying of powdery, granular and small abrasive or non-abrasive materials, such as silica sand, cement, coal, limestone, dry clay, gypsum, etc.

Capacity: 15-380 m³/h.

VFS Pneumatic Butterfly Valve

VFS butterfly valve can be applied to the processing of all powdery and granular materials. The valve uses the material’s own gravity to intercept flow and pneumatically transmit dry materials. VFS can be installed under hoppers, bins, silos, screw or other types of conveyors, as well as connected to pneumatic conveying pipes. Due to the special construction of this valve and the use of engineered materials, it is always a very economical and highly efficient option.

Diameter: 100mm, 150mm, 200mm, 250mm, 300mm, 350mm, 400mm.

Roots blower Pressure Conveyance

The equipment uses air energy as the power medium, according to the characteristics of different materials, it is equipped with a special feeding device, supplemented by various valves and special pipes, and is precisely designed. According to the production needs, the system can adopt two different feeding forms, such as dense-phase song-type batch conveying or dilute-phase continuous conveying. The system can be used for the transportation of redispersible latex powder, cellulose, various functional additives, calcium powder, vitrified microbeads, fine sand and other powders or fine particles.

Distance: 80-600 meters.

Capacity: 15-300 cuber meter per hour.