5t/h mortar mixing equipment

Item: Simple dry mortar mixing equipment

Production capacity: 5-8 tons per hour

Application: Wall putty, tile adhesive, cement mortar etc.

Labor cost: 2-4 workers

Power: 15-25 kw

Mixer type: Ribbon mixer

Packing machine: Valve bag packing

Cycle time: 10 mins

Installation and training: Provided

Introduction

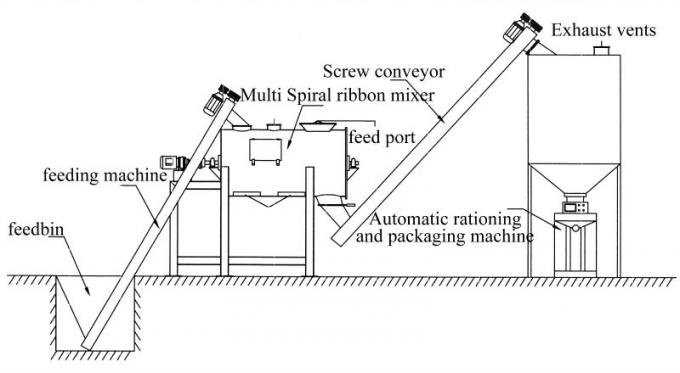

On the basis of the multi-spiral ribbon dry powder mortar mixer, this dry powder mortar production line adds a secondary lifting screw conveyor, a finished product hopper and an automatic valve packaging machine. From feeding to a complete set of simple dry powder mortar production line, automatic mixing, filling and packaging production process.

Customer factory

Features

1. The inner and outer multi-layer ribbons are used for mixing, no mixing dead angle, fast mixing speed and high uniformity.

2. The horizontal cylinder structure is adopted, with stable operation, low noise, long service life, convenient installation and wide application range.

3. Equipped with electric screw elevator, feeding is convenient and fast.

4. There is a movable door under the body, which is convenient for cleaning.

5. Less investment, small footprint, easy operation and obvious effect

Application of Simple Dry Mortar Mixer

The simple dry construction mixture mixing plant can produce the following dry powder mortar:

Bonding mortar: masonry mortar, wall and floor tile bonding mortar, anchoring mortar, etc.

Decorative mortar: decorative plaster, interior and exterior wall putty, colored decorative mortar, etc.

Protection mortar: waterproof mortar, anti-corrosion mortar, self-leveling mortar, wear-resistant mortar, thermal insulation mortar, sound insulation mortar, repair mortar, mildew-proof mortar, shielding mortar, etc.