Analysis of the four common problems of external thermal insulation walls: shedding / cracking / condensation / hollowing.

The time when wall problems occur in the external wall insulation layer generally occurs after a period of time after the construction is completed, or after the temperature cycle changes in winter and summer, and the hidden quality or construction problems cause these problems. Generally speaking, there are four major problems.

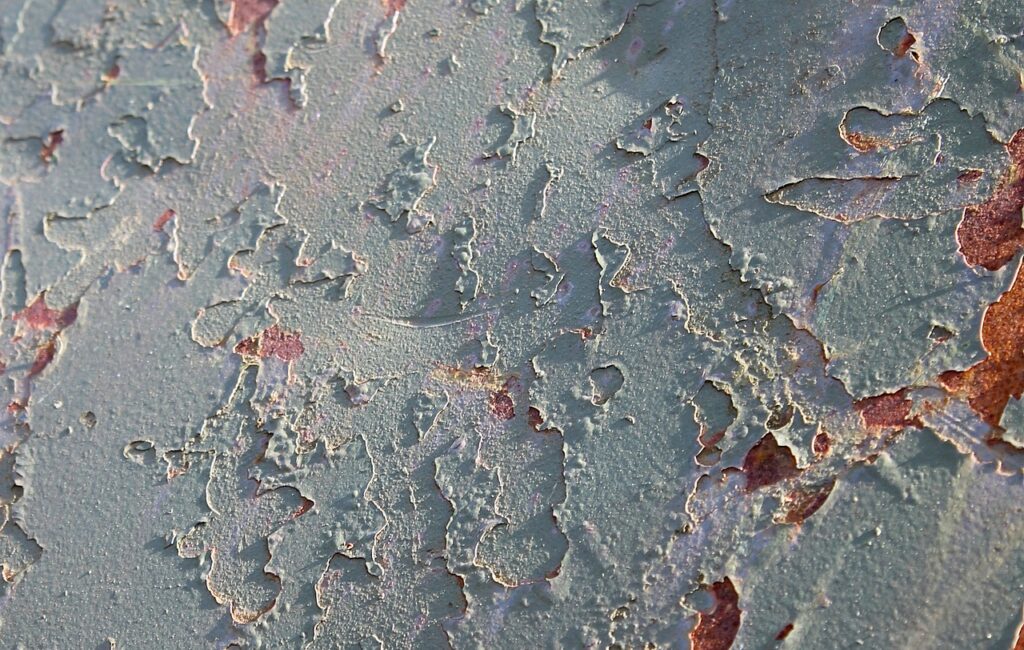

Exterior wall insulation peeling off

Due to the quality of the materials used and the carelessness in the construction process, the external wall insulation board is prone to displacement, hollowing and falling off, and the slurry insulation layer has hollowing and falling off. If it is not dealt with in time, the thermal insulation effect of the wall will be greatly reduced.

reason:

1. Basic structural factors. The outer wall of the frame structure is prone to damage to the insulation layer caused by the deformation of the masonry at the joints between the concrete beams and columns and the masonry. Scaffolding holes, etc. are not solidly built, and the local base layer of the thermal insulation layer is not strong and damaged. The decorative components of the exterior wall are not firmly fixed and displaced, resulting in a push-pull effect, which makes the insulation layer partially hollow and sees water for a long time after cracking, which eventually causes the insulation layer to fall off;

2. Improper anti-stress measures. The surface load of the insulation board is too large, or the negative wind pressure resistance measures are unreasonable. For example, the non-nail bonding method is used for the outer wall of coastal areas or high-rise buildings, which is very easy to cause the insulation board to be damaged by wind pressure and fall off.

3. Improper handling of the wall interface. Except for the clay brick wall, other walls should be treated with interface mortar and then coated with slurry insulation material, otherwise it is easy to cause the insulation layer to be hollowed directly or the interface treatment material to fail, resulting in the hollowing of the interface layer and the main wall, and the formation of a hollow insulation layer. drum. The surface of the insulation board also needs to be treated with interface mortar, otherwise it will also cause partial hollowing of the insulation layer.

Cracks in the plastering layer

The external wall thermal insulation plastering layer is composed of plastering mortar and reinforcing mesh. The plastering mortar is divided into bottom layer mortar and surface layer mortar. It is understood that when plastering the surface layer construction, first apply the bottom layer mortar on the surface of the installed external thermal insulation board, add a reinforcing mesh, apply the reinforcing mesh to the bottom layer mortar, and then apply the surface layer mortar on top, the thickness shall not be less than 3 mm, must be exposed grain but not exposed net.

Plastering mortar, also known as anti-crack mortar or anti-crack mortar, plays a key role in the entire external thermal insulation system, and builds a reliable and reinforced protective layer for the external thermal insulation board. The cracked plastering layer cannot solve the problems of thermal insulation, heat insulation, wind pressure resistance, fire resistance, freeze-thaw resistance, waterproof, weather resistance, flame retardant, ventilation, cracking, etc.

Indoor condensation

Because there are too many decorative lines picked out of concrete in the inner wall, and the proportion of concrete pouring has been determined during thermal insulation, the thermal insulation treatment of this part is abandoned. These exposed concrete parts without thermal insulation treatment will cause frost in the room. , Condensation phenomenon, easily lead to damp and moldy walls.

Exterior wall bricks are hollow and falling off

It is not uncommon for the news of external wall tiles and materials to fall off and cause injuries. Quality problems caused by mistakes in construction and the influence of temperature may be one of the factors that cause problems with external wall tiles. In addition to making the wall look unsightly, empty and falling tiles are also prone to accidents.

reason:

1. Temperature changes. The temperature difference changes in different seasons and day and night make the facing bricks affected by the temperature stress in the three-dimensional direction, and the facing layer will generate local stress concentration in the vertical and horizontal walls or the junction of the roof and the wall. The local extrusion of the adjacent tiles will cause the tiles to fall off;

2. Material quality. Because the plastering mortar layer is deformed and hollowed out, the face bricks fall off in a large area; the composite wall is composed of incompatibility of the materials of each layer and the deformation is not coordinated, resulting in the displacement of the face bricks; the waterproof measures of the outer wall are not in place. Causes moisture to penetrate, causing repeated freeze-thaw cycles, causing damage to the adhesive layer of the tiles and causing the tiles to fall off;

3. External factors. Some external factors can also cause the tiles to fall off. For example, the uneven settlement of the foundation causes the deformation and dislocation of the wall of the structure, resulting in severe cracking of the wall and falling off of the tiles. Natural factors such as wind pressure and earthquakes can also cause the tiles to fall off.

In view of the above factors, we need a set of special equipment to produce t external wall insulation mortar. The erternal wall insulation mortar production line must be equipped with a complete set of automated production lines to ensure the accuracy of the production formula.